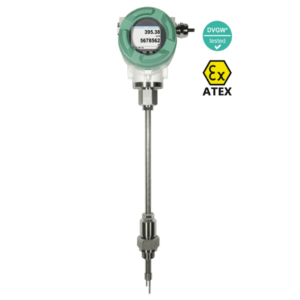

Technical data VA 400

| Parameters: | m³/h, l/min (1000 mbar, 20°C) in case of compressed air resp. Nm³/h, Nl/min (1013 mbar, 0°C) in case of gases |

| Adjustable via software: | m³/h, m³/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min |

| Adjustable via keypad: | diameter for volume flow calculation, counter resettable |

| Meas. principle: | calorimetric measurement |

| Sensor: | 2 x silicium chip |

| Meas. medium: | air, gases |

| Gas types adjustable via software: | air, nitrogen, argon, nitrous oxide, CO2, oxygen |

| Meas. range: | see table at page 54 |

| Accuracy: | ± 4 % m.v. ± 3 % m.v. via 5 point ISO precision calibration |

| Operating temp.: | -30…110 °C probe tube -30…80 °C housing |

| Operating pressure: | up to 50 bar |

| Analogue output: | 4…20 mA for m³/h resp. l/min on request: scaling for cfm, m³/min, l/min, l/s, ft/min, m/s |

| Pulse output: | 1 pulse per m³, signal high 24 VDC, for 30 ms |

| PC connection: | SDI interface |

| Power supply: | 24 VDC |

| Burden: | < 500 Ω |

| Housing: | polycarbonate |

| Probe tube: | stainless steel, 1.4301 mounting length 220 mm, Ø 10 mm |

| Mounting thread: | G 1/2“ |

| Ø housing: | 65 mm |