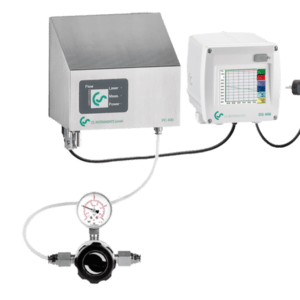

TECHNICAL DATA OIL-CHECK 400

| Measured medium: | Compressed air, free from aggressive, corrosive, acid, toxic, flammable and oxidising components |

| Measuring unit: | Residual oil content in mg oil/norm m³ relative to 1.0 bar [abs], +20 °C, 0% relative humidity, in accordance with ISO 8573-1 |

| Identifiable substances: | Hydrocarbons, functional hydrocarbons, aromatic hydrocarbons |

| Field of application: | After activated carbon filter, after activated carbon adsorber, after oil-free compressor, always with connected upstream filtration and dryer |

| Ambient temperature: | +5 °C… +45 °C, rel. humidity <= 75% without condensation |

| Pressure dew point: | max. +10 °Ctd. |

| Compressed air temp.: | +5 °C… +50 °C |

| Operational overpressure: | 3…16 bar [ü] optional pressure reducer connected upstream for up to 300 bar [ü] |

| Setting operational pressure: | By means of integrated pressure reducer with display |

| Humidity of measured gas: | <= 40% rel. humidity, pressure dew point max. +10 °C, non-condensable humidity |

| Compressed air connection: | G 1/8″ female thread according to ISO 228-1 |

| Measured values: | mg/norm m³, pressure and temperature compensated residual oil vapour content |

| Measuring range: | 0.001 … 2.5 mg/m³ |

| Detection limit (residual oil): | 0.001 mg/m³ |

| Flow of measuring gas: | approx. 1.20 norm litres/minute, relative to 1.0 bar [abs] and + 20 °C, in a relaxed state |

| Reference gas generation: | By means of integrated mini catalyst |

| Power supply: | 100…240 VAC / 1 Ph. / PE / 50…60 Hz / ± 10% |

| Outputs: | Ethernet interface (Modbus/TCP), RS 485 interface (Modbus-RTU), 2 alarm relays (change 230 VAC 3A), 4…20 mA (on request) |

| Operating hours counter: | integrated |

| Dimensions (mm): | 410 x 440 x 163 (W x H x D) |

| Weight: | approx. 16.3 kg |