CS Service Software – VA 5xx

CS Energy Analyzer Software Overview

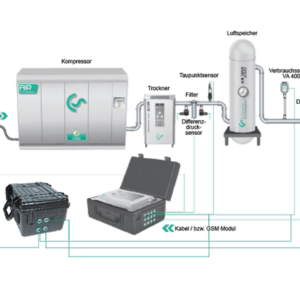

The CS Energy Analyzer Software provides a comprehensive understanding of compressor performance and energy consumption. The primary functionalities it offers are:

- Compressor Evaluation via Current and Power Metrics:

- Through a clamp-on ammeter, the energy consumption of each individual compressor is captured.

- Using the compressor’s performance data, the software calculates the amount of compressed air produced.

- Additional computations include:

- Energy consumption in kWh.

- Compressor’s load, unload, and stop durations.

- Compressor load percentage.

- Count of load/unload cycles.

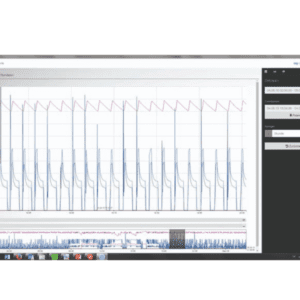

- Holistic System Analysis with Real Flow Metrics:

- This analysis mirrors the compressor evaluation but further incorporates real flow measurements using a flow sensor.

- By measuring the actual produced or consumed quantity of compressed air, the software can determine the volume and cost percentage of leakages in the system in relation to the total costs.

- Leakage Estimation:

- Leakages are computed during non-production times, such as shutdowns, weekends, or holidays.

- The flow sensor measures the volume of air provided. During these downtime periods, compressors maintain a consistent pressure, which means any air consumption can be attributed to leakages.

- Even in 24/7 production environments, there’s typically a brief window where all operations cease. The software utilizes this data to define a leakage rate and subsequently, the associated costs in €.

With the CS Energy Analyzer Software, businesses can optimize their compressor operations, minimize energy consumption, and mitigate costly leakages.

You may also like…

-

CS Leak Reporter V2 – Reporting Software for LD 500/510

Leak Detectors