The mobile transport trolley features:

- Stably mounted components of OIL-Check 400, PC 400, and FA 510

- Outer dimensions: 1.0 x 0.7 x 0.35 m (W x H x D)

- A mobile sampling system consisting of a 2 m PTFE hose and quick lock coupling (oil- and grease-free)

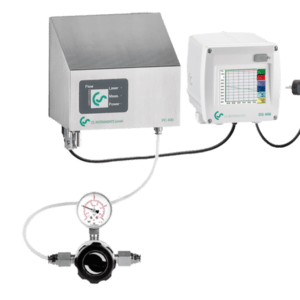

- A PC 400 particle counter up to 0.1 µm for compressed air and gases, complete with a pressure reducer/sampling hose, calibration certificate, and a Modbus-RTU interface

- An FA 510 dew point sensor, ranging from -80° to +20°Ctd, inclusive of a mobile measuring chamber and a 5 m connection cable for portable devices

- The DS 500 mobile, an intelligent chart recorder with 4 sensor inputs

- CS Basic, a software solution for data evaluation in graphic and tabular form, facilitating the reading of measured data via USB or Ethernet, and includes licenses for 2 workstations.