TECHNICAL DATA VA 525

| Parameters: | m³/h, l/min (1000 mbar, 20 °C) in case of compressed air or Nm³/h, Nl/min (1013 mbar, 0 °C) in case of gases |

| Units adjustable via keys at display: | m³/h, m³/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min, g/s, lb/min, lb/h |

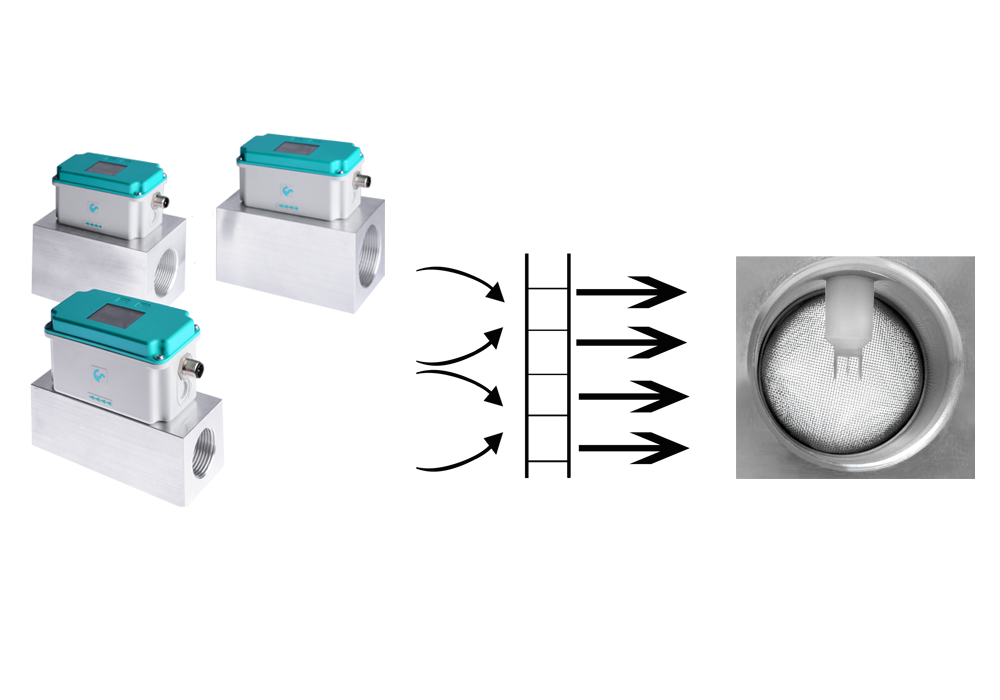

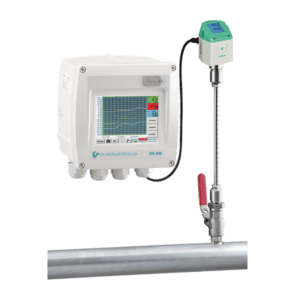

| Sensor: | Thermal mass flow sensor |

| Measured medium: | Air |

| Measuring range: | See table above |

| Accuracy: (o. M. V. = of measured value) (o. F. S. = of full scale) |

± 1.5% of m.v. ± 0.3 % of f.s. on request: ± 1% of m.v. ± 0.3% of f.s. or ± 6% of m.v. ± 0.5% of f.s. |

| Pressure measurement: | 0…16 bar, accuracy: 1%, or 10…2000 mbar (abs) |

| Operating temperature: | -20…60 °C |

| Operating pressure: | Up to 16 bar |

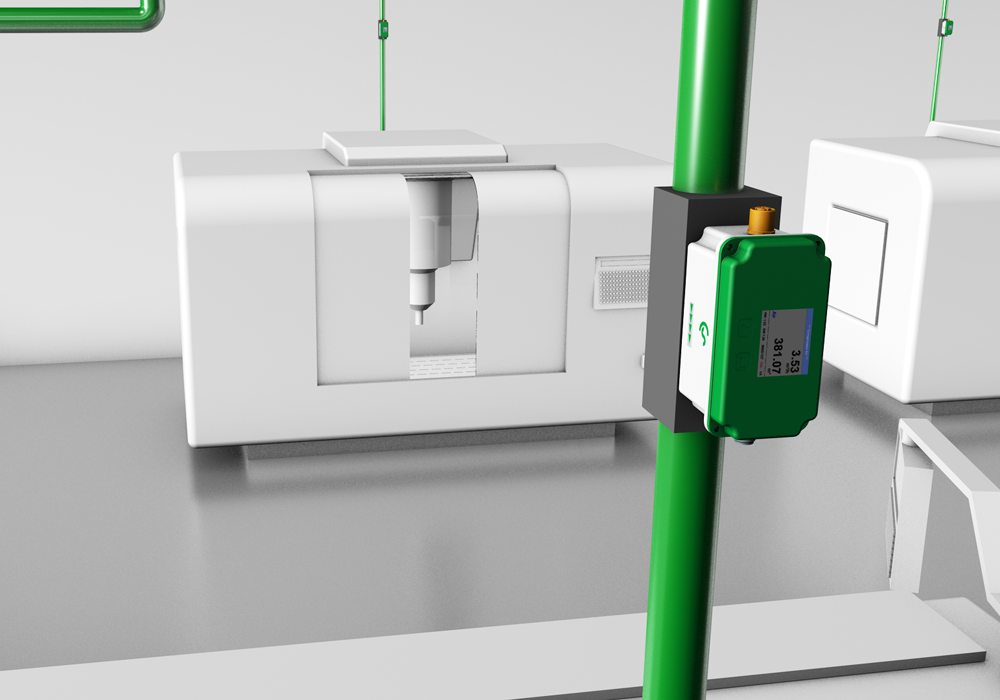

| Digital output: | RS 485 interface, (Modbus-RTU), M-Bus (optional) Ethernet interface or PoE |

| Analogue output: | 4…20 mA for m³/h or l/min |

| Pulse output: | 1 pulse per m³ or per litre electrically isolated. Pulse weight can be set on the display. Alternatively, the pulse output can be used as an alarm relay. |

| Supply: | 18…36 VDC, 5 W |

| Burden: | < 500 Ω |

| Housing: | Polycarbonate (IP 65) |

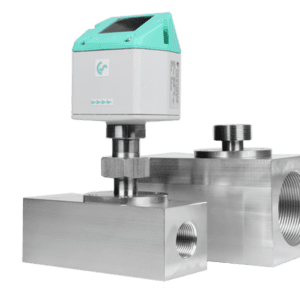

| Measuring section: | Aluminium |

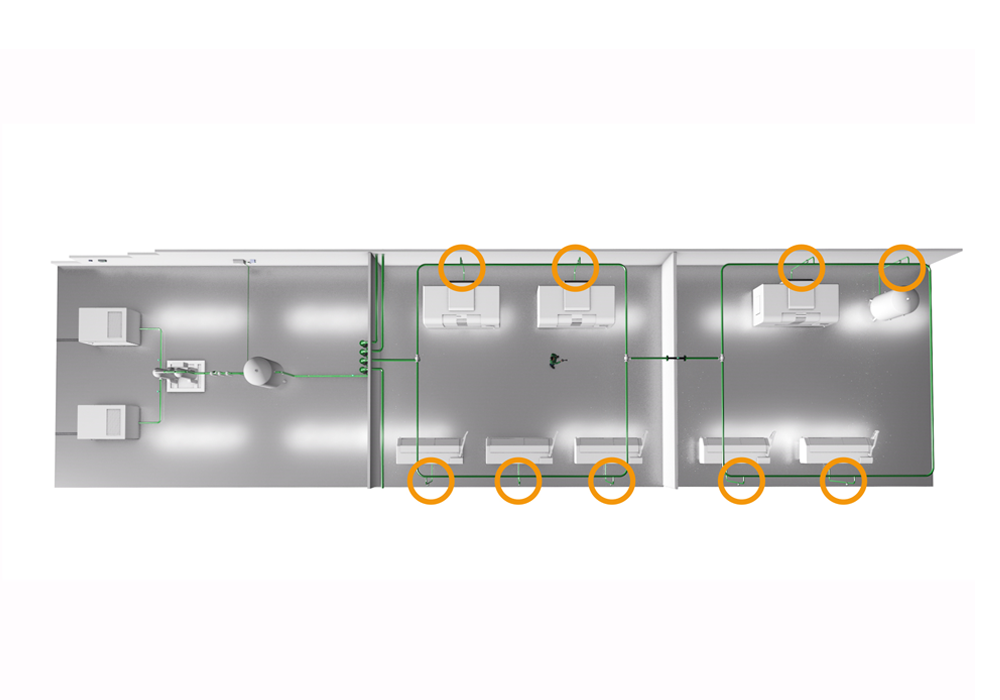

| Connection thread of measuring sections: | G 1/4″ to G 2″ (BSP British Standard Piping) or 1/2″ to 2″ NPT thread |

| Mounting position: | any |